November 2022

XTO Energy Deploys Muddy Boots “Measure” for Meter Management and Field Calibration

Background

In 2021 XTO Energy, an ExxonMobil subsidiary (XTO), faced a challenge with their field calibration software. There was a need to upgrade the existing system to a new release, an expensive and time-consuming proposition. From their view, the existing system had been pieced together through acquisitions, become dated, and was frustrating to use. The system was also slow and cumbersome, often taking technicians in excess of 45 minutes to record a single calibration.

Furthermore, the software could not be trusted to synchronize properly and was subject to entire servers (including connected laptops) becoming corrupted if technicians made local configuration changes on their laptops.

There was significant IT burden and cost to support what amassed to 17 dedicated servers across the US and a need for administrators to spend 2 to 3 hours setting up each individual technician laptop, with little hope that they would not soon become corrupted and have to be reconfigured again.

Lastly, the existing system lacked the ability to provide compliance feedback to users with respect to the regulations dictated by the BLM and calibration tolerance requirements defined by XTO company standards and Industry Standards.

XTO felt that there should be a better solution and evaluated a number of alternatives. Among those was a product called Muddy Boots Online. XTO had previous experience using Muddy Boots for measurement flow diagrams [site facility diagrams] and in Canada, the system was being used for a number of other functions including the management of compositional data and meter calibrations.

According to Jason DeWitt, Measurement Manager, XTO had an excellent relationship with Muddy Boots Inc and believed the Company would be able to meet their needs while remaining committed to providing a product that was both more user-friendly and eliminated many existing compliance concerns.

He chose Muddy Boots because “Muddy Boots brings efficiencies and scalability of cloud-based software, carries a significantly lower overall cost, and the Company has a proven track record for timely delivery and valuing customer experience.”

Application Pilot

XTO elected to conduct a pilot and test the capabilities of the system prior to rolling it out across their various business units. The pilot was conducted in one field that was chosen based on the diversity of equipment and types of field activities to provide the broadest possible test of the system.

This effort was conducted in concert between both head office and field staff. The pilot proved that the system worked well offline, was flexible for varying process needs, was intuitive for technicians to learn, and was easy to set up and maintain.

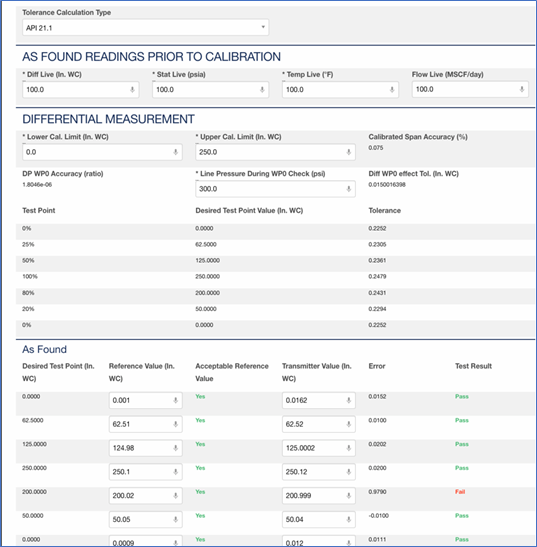

Through the pilot, XTO realized they could have exacting control of their processes, and oversight of measurement compliance. For example, incorporating logic and existing equipment information into forms that provide immediate feedback to the user regarding completeness and compliance with BLM and Industry Standards (e.g. test points, tolerances).

System Configuration

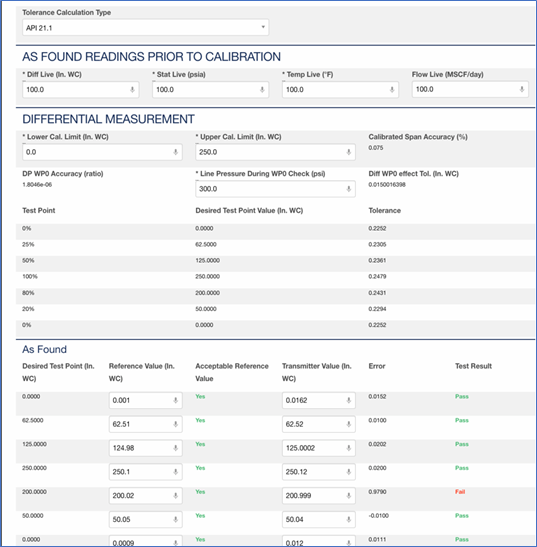

One of the key benefits of Muddy Boots is that forms used in the field can be customized to meet client-specific needs. XTO defined exactly what their calibrations would look like, and what the related meter management processes were.

They scoped an intelligent multi-variable calibration form purposed for ensuring that the technician in the field completing the form is not burdened with unnecessary data entry or off-hand unit conversions/calculations, freeing up valuable time to focus on accurate and safe completion of the task at hand, while also reducing mistakes and errors.

Some of these intelligent features include:

- Specific functionality by meter purpose/use.

- Automated selection of calibration equipment with indication on the form regarding the status of certification.

- Logic to guide the user to the required tolerances and automatic determination of the test points in order to be compliant with XTO company standards, API MPMS 21.1, and local/federal regulations.

- “Reason for Test” selection on the form, which toggles fields and form functionality. For example, “new install” allows for the direct entry of transmitter and equipment details at time of installation.

- Mandatory fields for calibration compliance and form verification to ensure the calibration record is complete.

- Pass/Fail flagging of each section and overall “Calibration Acceptable” flag to visually show the user if the calibration is compliant and if not, which part of the test needs to be addressed.

- Automatic population of critical meter details to reduce technician-required inputs and associated errors.

XTO required an additional set of forms to be used in the field. These forms included:

- Meter Purpose/Class record, which drives the calibration logic and the schedule frequency

- Secondary Instrumentation Test (MVS, Static, Differential, & Temperature)

- Chart Recorder Tests

- Meter Tube Inspections

- Meter Diagnostics Record

- Meter Prove Report

- Liquid & Gas Sample Analysis

- Calibration Equipment Recertifications

- Weigh Scale Certification

Due to XTO operations in Argentina, all forms were also translated to Spanish with appropriate units of measure (metric) incorporated.

Figure 1 – Partial Display of Calibration Form

Meter Information Table (MIT) Configuration

In addition to new forms and field processes, XTO configured Muddy Boots as the “Meter Master” data repository, or what XTO refers to as their MIT. All meter data (e.g. Purpose, Class, Value), as well as calibrations, are stored together in Muddy Boots. Forms and processes were configured for loading new meters and maintaining the meter data. Actions taken directly in the field are now immediately reflected in the meter master data.

The Muddy Boots form feature that allows data elements to be loaded on a transaction basis and copied back to the MIT, was very helpful here. A full history of meter data can now be maintained and accessed in a single location.

A key process for XTO is their annual Meter Purpose and Class Review. Here, XTO compares meter throughput and revenue to its current “Purpose” and “Class”. This data is loaded into Muddy Boots on a yearly basis to keep an updated MIT record for each meter. This data drives the calibration tolerances and the calibration frequency. This tight integration of meter data and process means compliance requirements are unanimously understood by all involved and consistently met.

Preparing for Implementation

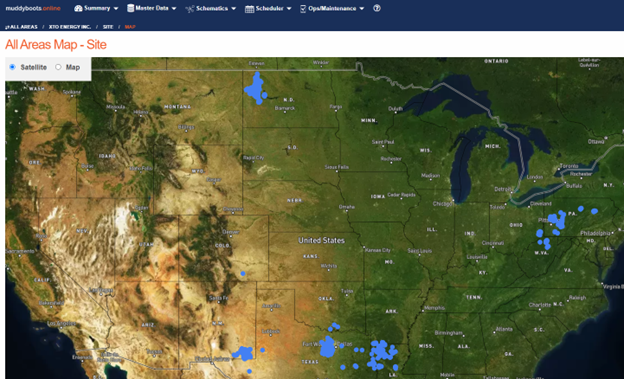

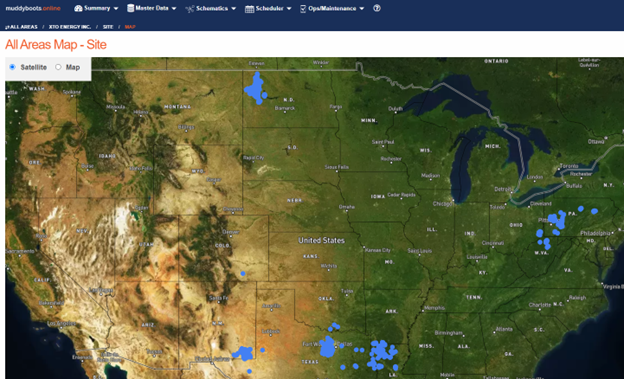

To prepare for implementation XTO had to load all meter data in Muddy Boots, load the calibration equipment, load all the schedules, and train over 200 users. All data is tied to geographic locations and the Muddy Boots map feature allows one to focus on asset subsets or schedules by geographic location.

Figure 2 – Partial Map of Meter Locations

XTO loaded over 20,000 meters and in aggregate, 55,000 scheduled tasks were loaded. The import/export features of Muddy Boots facilitated the data loads. Part of the implementation was to also incorporate pre-existing measurement flow diagrams, creating the connection between meters illustrated on schematics and those being used to perform calibrations.

Muddy Boots staff performed the process of matching existing meters with the correct drawings and consolidating data into the correct Fields, Regions, and Districts.

Implementation

Muddy Boots went live, across XTO, on September 12th. All 150+ technicians started completing calibrations that week as well as additional activities: sampling, orifice plate checks, etc.

The system worked exceptionally well and continues to operate without issue. Within the first month, there were over 5,000 calibrations and associated activities recorded in the system. The transition was efficient and effective.

Benefits

Polling the XTO head office staff about the change they offered the following feedback regarding benefits:

- The standardization of the calibration form has led to increased efficiency in data management.

- There are significant administrative savings: users can be set up in minutes. Schedule and other system adjustments are instantaneous.

- New meter information is captured quickly by field staff, saving time and increasing accuracy.

- Immediate access to all recorded information the moment it is captured in the field.

- Confidence and ability to quickly assess compliance with Industry Standards and BLM.

- Ready access to information and workflow capabilities means that supervisors and management are instantly aware of concerns that require attention and have full, curated access to this data 24/7.

- Clear audit trails in the system to see when changes have been made and who made them.

- Drastically improved above-field support. If a user is having an issue, XTO support can log into MBO and view the exact meter that the user is having an issue with and help them accordingly.

“Muddy Boots’ greatest value proposition could possibly be their understanding of field operations paired with humility and willingness to continuously grow their product along with customer needs, as well as wants. Each interaction feels like a long-term investment in our joint partnership.” Jason DeWitt, Measurement Manager, XTO Energy, an ExxonMobil Subsidiary

Field staff also reflected positively, noting:

- The calibration guides you through the decisions required to get the correct result.

- The calibrations equipment dropdown saves time and increases accuracy. It also highlights if calibration equipment recertification is due. Recertifications can be scheduled side by side with meter calibrations ensuring they are not missed.

- The offline system works seamlessly without the need to hit a synchronize button.

- Problems in the field that prevent the successful completion of a calibration are easily recorded for follow-up with the Muddy Boots “corrective action” feature.

- Field users can record and track data associated with meters that do not necessarily require the completion of a calibration form. The “Misc Task” activity allows users to record items such as replacement of batteries, cleaned solar panels, repaired/replaced loose wires, etc. This allows tracking for reliability studies or root cause analysis.

- Training was easy. The software is modern and very user-friendly.

- Work schedules, visible via the calendar display, can be easily adjusted. Many groups review their calibration schedules to better distribute work across resources and the year.

- Essentially, Muddy Boots saves time for the field staff by significantly reducing the effort to record a calibration and ensure its accuracy.

Nathan Mills, the implementation project leader, also speaks positively of his experience working with the Muddy Boots team.

“The system works extremely well and is adaptable to our needs. The Muddy Boots team handled virtually everything we threw at them. The implementation was smooth, and we shut down our old system the second day!”

Looking Forward

XTO is considering the use of Muddy Boots for additional measurement functions, and in other departments where operational data is captured and stored. XTO Energy Inc sees a bright future for Muddy Boots in their organization!

Learn more about Muddy Boots Measure and schedule your demo today.